B2S Corporation

Proudct

Virgin Liner

Virgin liner products are typically made from 100% new or virgin raw materials without any recycled or reprocessed content. The content of a virgin liner can vary depending on the specific industry and application, but here are some common materials used in virgin liner products:

- Additives: Virgin liners may include additives to enhance specific properties or performance. These additives can include slip agents to reduce friction, antiblock agents to prevent sticking, or anti-static agents to reduce static electricity buildup. Other additives, such as UV stabilizers, antioxidants, or colorants, may also be incorporated to improve durability, stability, or aesthetics.

- Thickness: Virgin liners are available in various thicknesses, depending on the application requirements. The thickness can range from thin films (measured in micrometers) to thicker sheets (measured in millimeters). The chosen thickness depends on factors like strength, flexibility, and barrier properties needed for the specific application.

- Surface Treatment: Some virgin liners may undergo surface treatments to enhance specific characteristics. For example, surface treatments like corona treatment or flame treatment can improve the liner’s adhesion properties, allowing for better bonding with adhesives or printing inks.

- Transparency or Opacity: Virgin liners can be transparent, allowing visibility of the packaged contents, or opaque, providing a non-transparent barrier. The choice of transparency or opacity depends on the application requirements and the desired visual appearance of the packaged product.

- Applications: Virgin liners find applications in various industries, including food packaging, pharmaceutical packaging, industrial packaging, medical devices, construction materials, and more. The use of virgin materials ensures consistent quality, cleanliness, and performance in critical applications where hygiene, purity, or specific regulatory requirements are essential.

B2S Corporation

Proudct

Kraft Liner

Kraft liner, also known as Kraftliner, is a type of paperboard primarily used for packaging applications that require strength, durability, and resistance to moisture. It is commonly used for manufacturing corrugated boxes and other packaging materials. Here is some information about Kraft liner:

- Composition: Kraft liner is made from high-quality virgin wood pulp, typically obtained from softwood trees such as pine or spruce. The wood fibers are processed and refined to produce a strong and durable paperboard.

- Brown Appearance: Kraft liner has a characteristic brown color, which comes from the natural color of the wood fibers used in its production. This brown appearance is often desired for its natural and rustic look.

- Strength and Durability: Kraft liner is known for its strength and durability. It offers excellent tensile strength, tear resistance, and puncture resistance, making it suitable for demanding packaging applications that require protection and support for the packaged goods.

- Moisture Resistance: Kraft liner has inherent resistance to moisture, providing a level of protection against humidity and minor exposure to liquids. However, it is not completely waterproof and may require additional coatings or treatments for enhanced moisture resistance.

- Printability: Kraft liner can be printed on using various printing techniques, such as flexographic or offset printing. However, due to its brown color and coarse surface texture, the printing results may have a more rustic or textured appearance compared to white paperboards.

- Recyclability: Kraft liner is generally recyclable and considered environmentally friendly. It is often made from sustainably sourced fibers and can be recycled to produce new paper products.

- Corrugated Packaging: Kraft liner is commonly used as the outer layer of corrugated board, which is widely used in the packaging industry. Corrugated board consists of multiple layers of Kraft liner sandwiched with a fluted layer (usually made of recycled paper) to provide strength, cushioning, and protection for the packaged goods.

- Customizability: Kraft liner can be customized in terms of thickness, weight, and surface treatments to meet specific packaging requirements. Different grades of Kraft liner are available to cater to various packaging needs, ranging from lightweight to heavyweight options.

B2S Corporation

Proudct

Test Liner

Test liner, also known as test liner, is a type of paperboard primarily used for packaging applications that require strength, durability, and resistance to moisture. It is commonly used for manufacturing corrugated boxes and other packaging materials. Here is some information about test liner:

- Composition: test liner is made from high-quality virgin wood pulp, typically obtained from softwood trees such as pine or spruce. The wood fibers are processed and refined to produce a strong and durable paperboard.

- Brown Appearance: test liner has a characteristic brown color, which comes from the natural color of the wood fibers used in its production. This brown appearance is often desired for its natural and rustic look.

- Strength and Durability: test liner is known for its strength and durability. It offers excellent tensile strength, tear resistance, and puncture resistance, making it suitable for demanding packaging applications that require protection and support for the packaged goods.

- Moisture Resistance: test liner has inherent resistance to moisture, providing a level of protection against humidity and minor exposure to liquids. However, it is not completely waterproof and may require additional coatings or treatments for enhanced moisture resistance.

- Printability: test liner can be printed on using various printing techniques, such as flexographic or offset printing. However, due to its brown color and coarse surface texture, the printing results may have a more rustic or textured appearance compared to white paperboards.

- Recyclability: test liner is generally recyclable and considered environmentally friendly. It is often made from sustainably sourced fibers and can be recycled to produce new paper products.

- Corrugated Packaging: test liner is commonly used as the outer layer of corrugated board, which is widely used in the packaging industry. Corrugated board consists of multiple layers of test liner sandwiched with a fluted layer (usually made of recycled paper) to provide strength, cushioning, and protection for the packaged goods.

- Customizability: test liner can be customized in terms of thickness, weight, and surface treatments to meet specific packaging requirements. Different grades of test liner are available to cater to various packaging needs, ranging from lightweight to heavyweight options.

B2S Corporation

Proudct

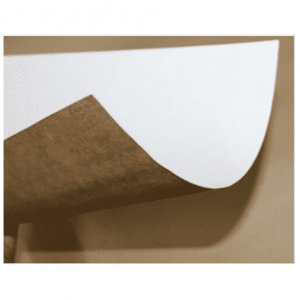

White Liner

White liner, also known as White liner, is a type of paperboard primarily used for packaging applications that require strength, durability, and resistance to moisture. It is commonly used for manufacturing corrugated boxes and other packaging materials. Here is some information about White liner:

- Composition: White liner is made from high-quality virgin wood pulp, typically obtained from softwood trees such as pine or spruce. The wood fibers are processed and refined to produce a strong and durable paperboard.

- Brown Appearance: White liner has a characteristic brown color, which comes from the natural color of the wood fibers used in its production. This brown appearance is often desired for its natural and rustic look.

- Strength and Durability: White liner is known for its strength and durability. It offers excellent tensile strength, tear resistance, and puncture resistance, making it suitable for demanding packaging applications that require protection and support for the packaged goods.

- Moisture Resistance: White liner has inherent resistance to moisture, providing a level of protection against humidity and minor exposure to liquids. However, it is not completely waterproof and may require additional coatings or treatments for enhanced moisture resistance.

- Printability: White liner can be printed on using various printing techniques, such as flexographic or offset printing. However, due to its brown color and coarse surface texture, the printing results may have a more rustic or textured appearance compared to white paperboards.

- Recyclability: White liner is generally recyclable and considered environmentally friendly. It is often made from sustainably sourced fibers and can be recycled to produce new paper products.

- Corrugated Packaging: White liner is commonly used as the outer layer of corrugated board, which is widely used in the packaging industry. Corrugated board consists of multiple layers of White liner sandwiched with a fluted layer (usually made of recycled paper) to provide strength, cushioning, and protection for the packaged goods.

- Customizability: White liner can be customized in terms of thickness, weight, and surface treatments to meet specific packaging requirements. Different grades of White liner are available to cater to various packaging needs, ranging from lightweight to heavyweight options.

White liner is widely used in various industries, including food and beverage, consumer goods, e-commerce, and industrial packaging. Its strength, durability, and natural appearance make it a popular choice for protecting and transporting goods while maintaining a sustainable and eco-friendly approach.