B2S Corporation

Proudct

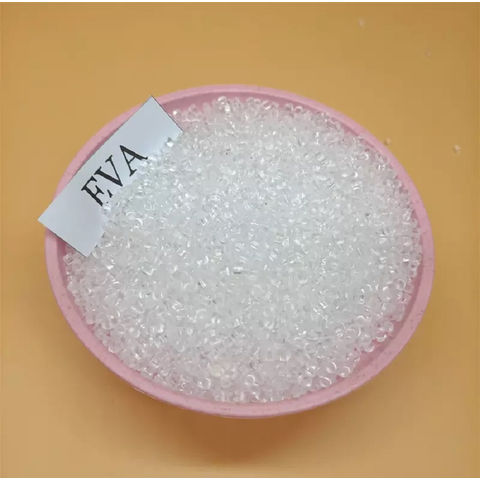

EVA Resin

EVA (Ethylene Vinyl Acetate) resin is a copolymer that is widely used in various industries due to its unique properties and versatility. It is a thermoplastic material composed of ethylene and vinyl acetate monomers. Here is some information about EVA resin:

- Composition: EVA resin is a copolymer composed of two main monomers: ethylene and vinyl acetate. The ratio of ethylene to vinyl acetate can vary, resulting in different grades of EVA resin with varying properties.

- Flexibility and Softness: EVA resin is known for its flexibility and softness. The vinyl acetate content in the copolymer determines the degree of flexibility, with higher vinyl acetate content resulting in a softer and more flexible EVA resin.

- Transparency: EVA resin is transparent in its pure form, allowing light to pass through it. However, the transparency can be modified by incorporating additives or fillers into the resin.

- Low-Temperature Flexibility: EVA resin retains its flexibility and softness even at low temperatures, making it suitable for applications where flexibility is required in cold environments.

- Good Toughness: EVA resin exhibits good toughness and impact resistance. It can withstand repeated impacts and deformations without breaking or cracking, making it suitable for applications that require durability and resilience.

- Excellent Elasticity: EVA resin has excellent elastic properties, allowing it to recover its original shape after deformation. This property makes it suitable for applications where cushioning and shock absorption are important, such as in footwear, sports equipment, and packaging.

- Adhesion: EVA resin has good adhesion properties, which allows it to bond well with various substrates. It can be easily bonded to other materials using adhesives or through heat sealing processes.

- Chemical Resistance: EVA resin offers good resistance to chemicals, oils, and solvents. It is less prone to chemical degradation or damage, making it suitable for applications that involve exposure to various chemicals or harsh environments.

- Processability: EVA resin is easy to process using common thermoplastic processing techniques such as injection molding, extrusion, and blow molding. It can be molded into various shapes and forms to meet specific application requirements.

- Applications: EVA resin finds a wide range of applications across industries. It is commonly used in footwear, foam products, packaging materials, adhesive formulations, wire and cable insulation, solar cell encapsulation, and automotive components, among others.