B2S Corporation

Proudct

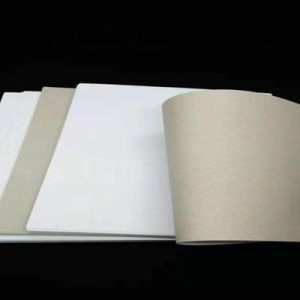

Duplex Board

Duplex board, also known as duplex paperboard, is a type of multi-layered paperboard that is widely used for packaging and printing purposes. It is composed of two layers, typically made from recycled fibers, that are bonded together to form a single sheet. Here is some information about duplex board:

- Composition: Duplex board is made from a combination of recycled fibers, such as waste paper or cardboard. The fibers are processed and formed into two separate layers, known as the back layer and the front layer. These layers are then combined and bonded together to create a sturdy and versatile paperboard.

- Two-Sided Coating: Duplex board is coated on both sides with a layer of clay or other coating materials. This coating enhances the surface smoothness, brightness, and printing properties of the paperboard. The coating also helps to improve ink absorption and color reproduction.

- Thickness and Weight: Duplex board is available in different thicknesses and weights, ranging from lightweight to heavyweight options. The thickness is measured in terms of the paper’s weight, which is expressed in grams per square meter (gsm) or pounds (lb). Common weights for duplex board range from 200 gsm to 450 gsm or higher.

- Printing and Packaging Applications: Duplex board is widely used in the printing and packaging industry. It is commonly utilized for packaging boxes, cartons, displays, book covers, file folders, and various other paperboard-based applications. Its sturdy construction and excellent printability make it suitable for both graphic printing and packaging purposes.

- Surface Finish Options: Duplex board is available in different surface finishes, such as gloss, matte, or uncoated. The choice of surface finish depends on the desired aesthetic appeal and the specific printing or packaging requirements.

- Strength and Durability: Duplex board is known for its strength and durability. It offers good bending resistance, tear resistance, and stiffness, making it suitable for applications where structural integrity is important.

- Recyclability: Duplex board is made from recycled fibers and is itself recyclable. This makes it an environmentally friendly option, as it reduces the demand for virgin fibers and minimizes waste in the paper industry.

- Customizability: Duplex board can be customized to meet specific requirements. It can be easily cut, folded, glued, and printed to create customized packaging solutions or promotional materials. Additionally, it can be embossed or laminated to add texture or enhance its visual appeal.