B2S Corporation

Proudct

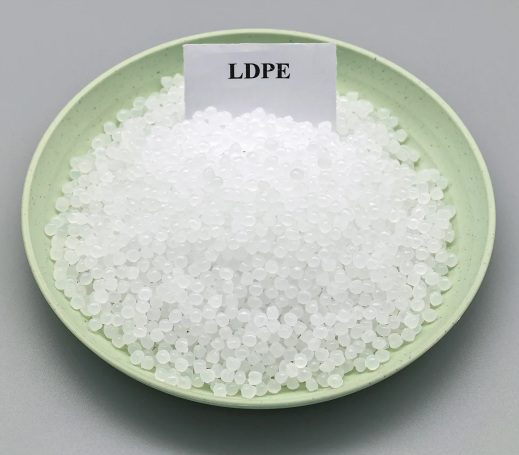

LDPE Film

LDPE (Low-Density Polyethylene) film is a versatile plastic product that is commonly used for various packaging and industrial applications. It is made from the polymerization of ethylene gas under high pressure and is characterized by its low density, flexibility, and excellent moisture barrier properties.

The content of LDPE film primarily consists of the following components:

- Polyethylene: LDPE film is composed primarily of polyethylene, which is a thermoplastic polymer. Polyethylene molecules consist of long chains of repeating ethylene monomer units.

- Additives: Various additives may be incorporated into LDPE film to enhance its properties and performance. Common additives include:

- Slip agents: These additives reduce the friction between the film surfaces, making it easier to handle and preventing blocking or sticking of films.

- Antioxidants: These additives help to prevent the degradation of LDPE film when exposed to heat, light, or other environmental factors.

- UV stabilizers: LDPE films used for outdoor applications may contain UV stabilizers to protect against the harmful effects of ultraviolet radiation, which can cause degradation and color fading.

- Anti-static agents: These additives reduce static electricity buildup on the film surface, preventing dust or dirt attraction.

- Colorants: LDPE film can be manufactured in various colors by incorporating colorants or pigments during the production process.

- Other additives: Depending on the specific application, LDPE film may contain additional additives such as anti-block agents, anti-fog agents, or processing aids to enhance specific properties or processing characteristics.

It’s important to note that the exact composition and content of LDPE film can vary depending on the manufacturer, product specifications, and intended application.