B2S Corporation

Proudct

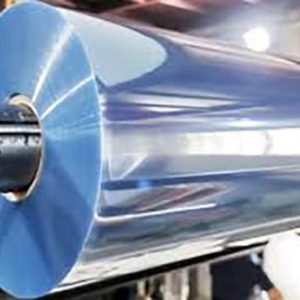

PVC Sheet

PVC sheets are flat, rigid panels made from polyvinyl chloride (PVC) resin. Here are some details regarding the content of PVC sheets:

- PVC Resin: PVC sheets are primarily composed of PVC resin, a synthetic polymer derived from petroleum. PVC resin is known for its durability, chemical resistance, and versatility. It undergoes a manufacturing process to form flat sheets of various sizes and thicknesses.

- Plasticizers: PVC sheets may contain plasticizers, which are additives that improve flexibility and workability. Plasticizers help make the PVC sheets more pliable and easier to shape or bend. Common plasticizers used in PVC sheets include phthalates, such as diisononyl phthalate (DINP) or di(2-ethylhexyl) phthalate (DEHP).

- Stabilizers: Stabilizers are added to PVC sheets to enhance their resistance to heat, UV radiation, and other environmental factors. Stabilizers help prevent PVC from degrading or discoloring due to exposure to sunlight or high temperatures. Common stabilizers used in PVC sheets include lead-based compounds, calcium-based stabilizers, or organotin compounds.

- Impact Modifiers: Impact modifiers are additives that improve the impact strength and toughness of PVC sheets. They help the sheets resist cracking or breaking under impact or stress. Common impact modifiers used in PVC sheets include acrylic modifiers, chlorinated polyethylene (CPE), or methyl methacrylate butadiene styrene (MBS).

- Fillers and Reinforcements: Some PVC sheets may contain fillers or reinforcements to enhance specific properties. Fillers, such as calcium carbonate or talc, can be added to improve stiffness or reduce cost. Reinforcements, like fiberglass or carbon fiber, can be incorporated to increase strength and dimensional stability.

- Colorants: PVC sheets can be manufactured in various colors by adding pigments or dyes to the PVC resin. The colorants provide visual appeal and can be customized to suit specific applications or design requirements.

- Additives: PVC sheets may include other additives to modify specific properties. These additives can include lubricants, anti-static agents, flame retardants, or antimicrobial agents, depending on the intended application of the PVC sheets.